The Future of Style: Exploring DTF Printing Innovation in the Textile Market

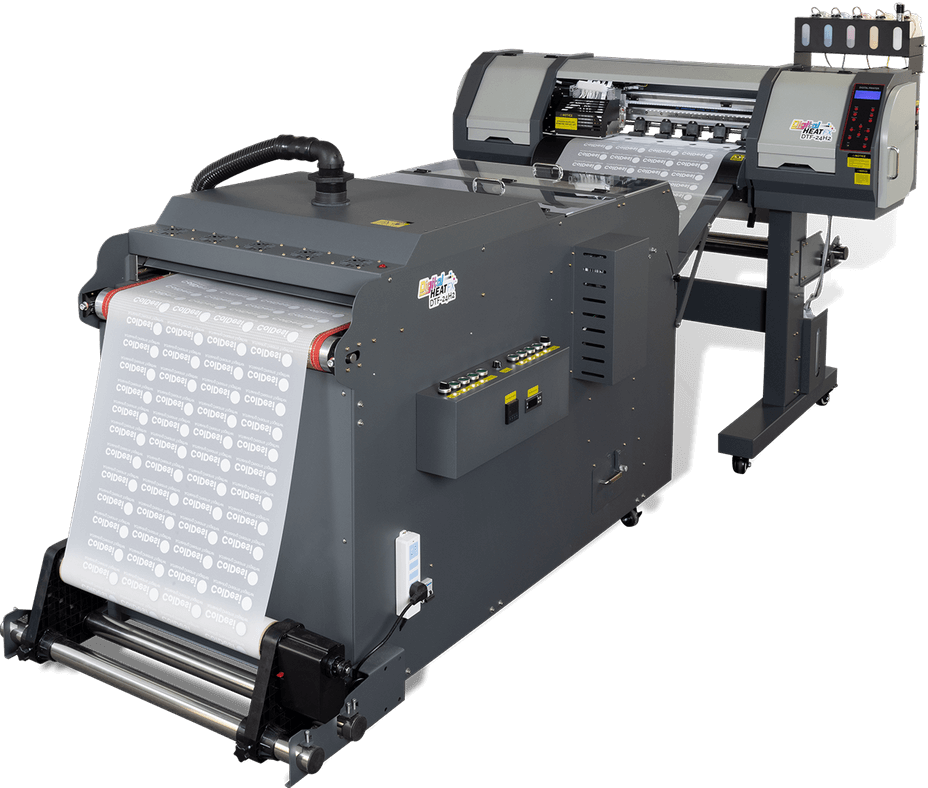

In the last few years, the fabric industry has actually seen a marked change towards cutting-edge technologies that are reshaping the landscape of style production. Amongst these improvements, Direct to Movie (DTF) printing technology has actually emerged as an appealing contender, providing unique abilities and opportunities for designers and suppliers alike. This innovative printing method has triggered interest because of its possible to reinvent conventional fabric printing procedures. As we delve right into the effects and possibilities of DTF innovation in the world of fashion, it ends up being noticeable that its integration could redefine market standards and lead the method for a new era of innovative expression and performance.

Advancement of Fabric Printing

Throughout background, the advancement of fabric printing has actually been a testimony to the cutting-edge innovations in this intricate art form. From the ancient worlds using techniques like block printing to the digital revolution of today, fabric printing has actually consistently pushed limits. The beginnings of fabric printing can be traced back to China around 220 AD, with making use of wooden blocks to publish on silk textiles. As the craft infect various other parts of the world, new methods such as display printing and roller printing arised throughout the Industrial Transformation, transforming the textile sector - DTF Printing.

The intro of electronic fabric printing in the late 20th century marked a considerable shift towards even more sustainable and flexible printing techniques. The advancement of textile printing showcases an abundant history of imagination, resourcefulness, and technological development in the globe of style and design.

Benefits of DTF Modern Technology

With the evolution of fabric printing strategies from ancient methods like block printing to contemporary technologies such as digital printing, the introduction of Direct-to-Fabric (DTF) innovation has actually significantly enhanced the effectiveness and sustainability of fabric printing procedures. One of the primary benefits of DTF innovation is its capacity to straight publish designs onto fabric without the requirement for transfer papers, which minimizes waste and streamlines the manufacturing procedure. Additionally, DTF printing permits greater color vibrancy and detail precision compared to standard techniques, making it possible for fabric manufacturers to develop high-grade and elaborate layouts effortlessly.

Furthermore, DTF innovation is understood for its adaptability, as it can be utilized on different sorts of materials, including natural fibers like cotton, woollen, and silk, along with artificial products such as polyester and nylon (DTF Printing). This versatility opens up a wide range of opportunities for makers and designers to try out different textures and products, causing more one-of-a-kind and ingenious products in the fashion business. Generally, the application of DTF technology stands for a considerable development in textile printing, using various advantages that add to the future sustainability and imagination of the industry

Sustainability in Style Production

Stressing green methods is paramount in modern fashion manufacturing, aligning with the expanding consumer demand for lasting products. Recently, the fashion business has dealt with increasing analysis due to its substantial environmental impact, consisting of you could try here extreme water use, chemical pollution, and fabric waste. As a response, lots of fashion brands are currently incorporating lasting practices right into their production processes to decrease harm to the atmosphere.

Sustainability in vogue production incorporates various elements, such as making use of organic and recycled products, reducing energy intake, implementing honest labor techniques, and advertising transparency throughout the supply chain. Furthermore, innovations in technology, like DTF printing, offer opportunities to additionally enhance sustainability in fabric production. This technology enables exact printing on textiles, reducing ink wastage and water usage compared to standard printing methods.

Design Flexibility and Personalization

Additionally, DTF printing helps with modification on a scale formerly unattainable, allowing for individualized clothes and one-of-a-kind pieces customized to private preferences. Generally, DTF printing technology reinvents the design landscape in the textile sector, providing limitless possibilities for innovative expression and tailored fashion.

Influence on Supply Chain & Market Trends

DTF printing technology in the textile industry is improving supply chain characteristics and affecting market fads through its efficiency and customization capabilities. By enabling on-demand printing and eliminating the demand for huge supplies, DTF modern technology enhances the supply chain procedure.

Moreover, the modification potential of DTF printing modern technology is changing the market patterns in website link the textile browse this site market. As an outcome, DTF innovation is driving a change towards even more cutting-edge and customer-centric methods within the fabric industry, shaping the future of style.

Verdict

To conclude, DTF printing technology is reinventing the fabric industry by using numerous advantages such as layout sustainability, customization, and freedom. This cutting-edge innovation is reshaping the future of style production, affecting supply chains, and driving market trends in the direction of a lot more green and reliable methods. As the market remains to develop, DTF printing will play an essential duty in forming the means fabrics are generated and consumed in the years to find.

From the ancient people using techniques like block printing to the digital revolution of today, textile printing has continually pressed boundaries. As the craft spread to other parts of the globe, brand-new techniques such as screen printing and roller printing arised during the Industrial Revolution, reinventing the textile market.

The intro of electronic fabric printing in the late 20th century marked a considerable shift towards even more flexible and lasting printing methods.With the development of textile printing methods from old approaches like block printing to contemporary innovations such as electronic printing, the introduction of Direct-to-Fabric (DTF) technology has significantly enhanced the effectiveness and sustainability of fabric printing processes (DTF Printing).In reaction to the imperative shift towards sustainability in fashion manufacturing, the adoption of cutting-edge technologies like DTF printing not just addresses environmental problems yet additionally opens up opportunities for unequaled style flexibility and personalization in the fabric industry